Discover the BUSA™ Seedbed Makers!

The BUSA™ Rotor is a fundamentally new working machine for seedbed preparation and ploughing, developed and patented by our company’s founder, Benedek Horváth.

This machine performs in a single pass the functions that traditional machines can only perform collectively. It performs the majority of these functions better than other machines.

Advantages of the BUSA™ Rotary Seedbed Makers

Efficiency

Due to the operating principle of the BUSA™ Rotor, it is more efficient and performs clod breaking, leveling, and covering better than machines with different operating principles.

It operates reliably at high working speeds with low specific traction requirements. The lifespan of the forged Swedish steel blades is exceptionally long.

Clogging-free operation

Preparing a seedbed on shallow mulch is not a problem for the BUSA™ Rotor. It does not gather crop residues and does not get clogged.

Adjustable rotors

The working depth can be easily and quickly adjusted for different soil moisture conditions, preventing the machine from forming clods in excessively wet layers.

Cage roller with internal cleaning

It does not get clogged even under extreme conditions. The machine certainly won’t be the obstacle to your work.

Early spring seedbed preparation

The BUSA™ Rotor performs its work not with its weight but with the dynamics of its blades, enabling early bed preparation on compacted soils…

where other machines would compact the moist zone below the hardened upper layer Early planting often results in a significant increase in yield.

Fall seedbed preparation

Creating a seedbed during the dry autumn can be challenging on compacted soils, but the BUSA™ Rotor dynamically strikes down and…

chops the surface more efficiently than any other machine, saving time and reducing soil compaction. With a well-prepared seedbed, germination is more secure

History of the product family

What exactly is a FKM?

FKM is the product name for our special seedbed maker, which is a combined machine typically consisting of two rows of BUSA™ Rotors, a levelling bar, a Slated roller element, and more recently, a row of front tines. Originally designed by Benedek Horváth for processing autumn plowing. Later, it was introduced as a BUSA™ product in its current form, and it gained popularity due to its high working speed and excellent clod-breaking ability. It was capable of creating a settled seedbed in one pass on freshly plowed fields.

A significant development was the patent for the adjustable angle BUSA™ Rotor, which allowed the cultivation depth to be adjusted to match the tillable layer With the increasing adoption of no-till cultivation, the need for creating spring beds on compacted areas became more frequent, which led to the addition of opening tines at the front of the machines. Other major advancements were the rubber roller finisher and the patented cage roller with internal cleaning, which made the BUSA™ Rotor the king of cultivation on compacted soils. In its current form, it can prepare seedbeds on time on soils where the hard surface used to require heavy machinery that caused significant and valuable water loss over an extended period.

Why is it worth using the BUSA™ machines?

The BUSA™ Rotor ensures a high level of operational safety, long lifespan, and low operating costs, while also providing yield increase and yield security for timely sown crops. According to farmers’ testimonials, significant losses have been avoided year after year by those who could sow early after using the BUSA™ FKM Seedbed maker.

In addition to being available in large working width versions, which, when combined with high working speed, result in a fast workflow, you can also save on fuel costs. There is no need to traverse the field 2-3 times for the perfect seedbed, which also reduces soil compaction.

Traditional cultivation

The BUSA™ Rotor was originally designed for traditional cultivation. It quickly became the uncrowned king of plowing finishers. is equally suitable for early spring cultivation as well as autumn work, and it excels in extreme conditions. It is also commonly used for crop residue management…

as it can be used to keep the field weed-free with low energy consumption. When equipped with a seed drill attachment, it is also suitable for broadcast sowing, thanks to its excellent mixing capabilities.

Tillage without rotation

The outstanding advantage of the BUSA™ Rotor is that it is resistant to clogging even on fields covered by crop residue. The covering function of the rotors helps in shallow incorporation of crop residues into the soil. The opener tines at the front of the machine also allow for cultivation in slightly compacted soils.

It is an excellent match, particularly for rapeseed cultivation, where the extra smooth seedbed facilitates easier harvesting.

Organic

In an organic production system, the interplay of technology is of paramount importance. The BUSA™ FKM is a ruthless weeding tool, allowing the plant the best chance in the competition against weeds by sowing immediately after seedbed preparation To ensure precise seeding and…

and row cultivation later on, a solid foundation is essential – a flat and uniformly compacted seedbed, which is achieved by the BUSA™ Rotor.

What exactly is the BUSA™ Rotor?

The BUSA™ Rotor is a seedbed maker and primary tillage finisher based on a completely novel concept. It was developed and patented by our founder Benedek Horváth in the beginning of the 80’s.

The BUSA™ Rotor is used on the fields, in between rows and on plantations. It has strong clot breaking and weeding capabilities, thanks to its high speed and acceleration.

A huge advantage of our Rotor compared to rigid tools is that is does not get clogged and does not throw the soil about, which make fast work without constant supervision possible.

What kind of configurations are available?

Everything you need to know about the components

Rollers developed and manufactured by BUSA

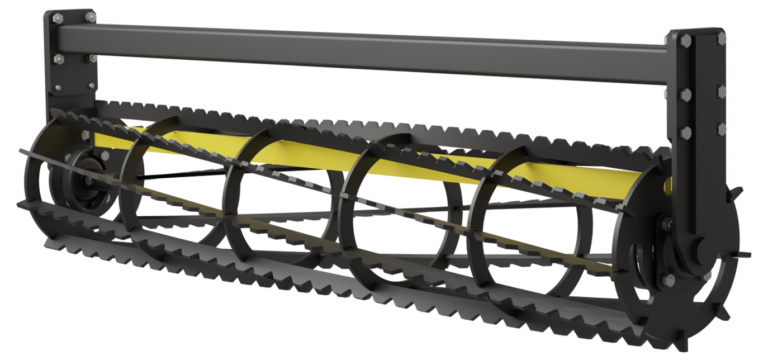

Slated roller

A clod breaking roller, typically used on Rotary seedbed makers and Disc harrows. It creates a fine clod structure on the surface while providing light compaction beneath. For wet soils, early spring…

seedbed preparation, we recommend the version with our patented internal scraper.

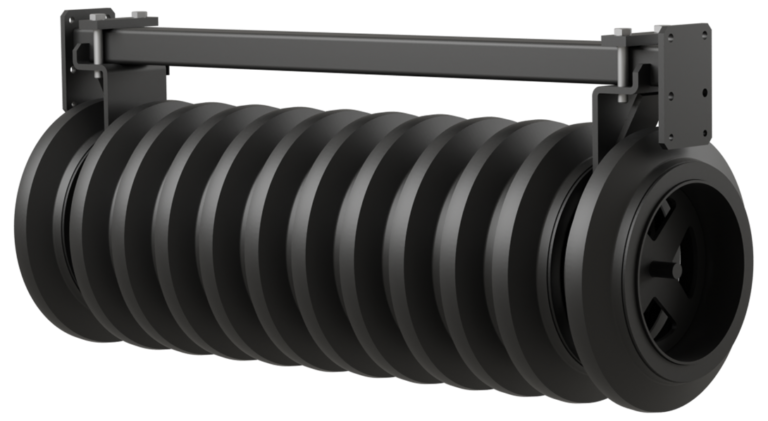

Rubber roller

The BUSA Rubber roller excels in wet soil conditions. Its custom-designed rubber elements deform upon contact with the soil, shedding mud stuck to them through deformation.

Soil cultivation is impossible where even this adapter gets clogged. It’s advisable to use it as a complementary tool paired with a slated roller, as it wears quickly under dry conditions.

Frame structure categories

Classic light

Our smaller machines are available in both fixed and foldable versions. They serve the same functions as the larger machines, but due to their lighter weight, they do not sink even on extremely loose soils .

Classic heavy

A well-developed structure that has evolved over the years through small steps It is available in both fixed and foldable versions. The three-part folding frame allows for a working width of over 8 meters, enabling stable and wide road transport.

Two section fold

A structure optimized for a small transport width, with the two wings folding vertically, making the machine not oversized. It is available with automatic working and transport position locking.

Mounted

Light and heavy, fixed and foldable machines can also be made in a mounted version. Its use can be justified for small parcels or simpler road transportation.

Working with a trailed machine is easier because it allows for turning without lifting, better longitudinal stability, but there are cases where the mounted version is an essential compromise.

Comparison

Classic light

WORKING WIDTH

2,7 - 4,7 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

8 - 14

MOUNTING

Mounted / trailed

TRANSPORT WIDTH

2,7 - 4,0 m

TRACTOR POWER

80 - 130 LE

WEIGHT

720 - 2.070 kg

Classic heavy

WORKING WIDTH

4,0 - 10,4 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

12 - 32

MOUNTING

Trailed

TRANSPORT WIDTH

3,2 - 4,0 m

TRACTOR POWER

120 - 260 LE

WEIGHT

2.400 - 7.550 kg

Two section fold

WORKING WIDTH

4,0 - 6,5 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

12 - 20

MOUNTING

Mounted / trailed

TRANSPORT WIDTH

2,4 m

TRACTOR POWER

120 - 200 LE

WEIGHT

1.800 - 3.300 kg

Mounted

WORKING WIDTH

2,7 - 6,5 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

8 - 20

MOUNTING

Mounted

TRANSPORT WIDTH

2,4 - 4,0 m

TRACTOR POWER

80 - 200 LE

WEIGHT

720 - 3.300 kg

Classic light

WORKING WIDTH

2,7 - 4,7 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

8 - 14

MOUNTING

Mounted / trailed

TRANSPORT WIDTH

2,7 - 4,0 m

TRACTOR POWER

80 - 130 LE

WEIGHT

720 - 2.070 kg

Classic heavy

WORKING WIDTH

4,0 - 10,4 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

12 - 32

MOUNTING

Trailed

TRANSPORT WIDTH

3,2 - 4,0 m

TRACTOR POWER

120 - 260 LE

WEIGHT

2.400 - 7.550 kg

Two section fold

WORKING WIDTH

4,0 - 6,5 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

12 - 20

MOUNTING

Mounted / trailed

TRANSPORT WIDTH

2,4 m

TRACTOR POWER

120 - 200 LE

WEIGHT

1.800 - 3.300 kg

Mounted

WORKING WIDTH

2,7 - 6,5 m

WORKING DEPTH

4 - 12 cm

ROTOR QUANTITY

8 - 20

MOUNTING

Mounted

TRANSPORT WIDTH

2,4 - 4,0 m

TRACTOR POWER

80 - 200 LE

WEIGHT

720 - 3.300 kg

Technical data

-

Classic light

-

Classic heavy

-

Two section fold

-

Mounted

Want a quote?

Pictures and videos

Frequently asked questions

The seedbed maker using BUSA™ Rotors is equipped with several solutions for extreme soil conditions. One of these solutions is the adjustable angle rotor. In the spring, it operates with a flat angle, which prevents it from digging deep into wet layers. Additionally, the machine features special components designed for wet soils, such as the rubber roller and cage roller with internal scraper. None of these components clog in wetter soils, allowing for efficient work even in moist soil conditions.

The BUSA™ Rotor is a perfect solution for mechanical weed control tasks, performing excellent covering and chopping functions without clogging. When using the seedbed maker equipped with a BUSA™ Rotor at a high angle, even a large amount of weeds won’t pose an obstacle for the machine.

At a flat angle setting, the working depth is the shallowest, typically cultivating only the dried upper soil layer during spring work. The highest number of blades are in the ground in this setting, which reduces the pressure per blade but works the layer more frequently.

The default, medium angle setting is recommended for normal conditions and soil states.

The steep angle setting offers the greatest working depth and the highest load per blade. This configuration is ideal for tasks like weeding, covering, and compacting freshly plowed soil where deeper soil cultivation is needed.

Preparing a seedbed on shallow mulch is not a problem for the BUSA™ Rotor. It doesn’t gather crop residues, and it remains unclogged.

The covering function of the rotors helps in shallow incorporation of crop residues into the soil.

With the BUSA™ FKM implement, a perfect seedbed can be made in a single pass.

The answer is that it depends on the soil type. However, here are some basic adjustment guidelines:

1. Frame is on level

2. Wheels in the air

3. Wings closed and secured

4. The machine resting on the rotors

5. Leveling bar setting: Make sure it neither carries too much nor too little soil. It carries too much soil when the rotors are deeply embedded in the ground. It carries too little soil when the cage roller scatters the soil unevenly on loose ground.

6. Setting the cage roller: the machine has to create a compact layer 5-6 cm deep below the surface, so that moist air cannot escape from the soil. You can check this using your heel. While in operation, the nuts around the spring-clamping bolts of the cage roller protrude about 2 cm from the spring plate.

7. Rotor angle – position adjustment: Fresh plowing with a lot of plant residues: use the highest angle-position. Spring leveling: use the flattest angle-position Spring seedbed: use a medium or larger angle-position.

In practice, they can be worn down to a point. At the halfway point, the blades should be rotated, moving the front row to the back.

You can always count on us!

- Need a spare part?

- Need to repair your machine?

- Need help with the setup?

- Would you prepare for next season?

- Interested in a used machine?

- How is the machine at work?